Frame E

by on in CG580

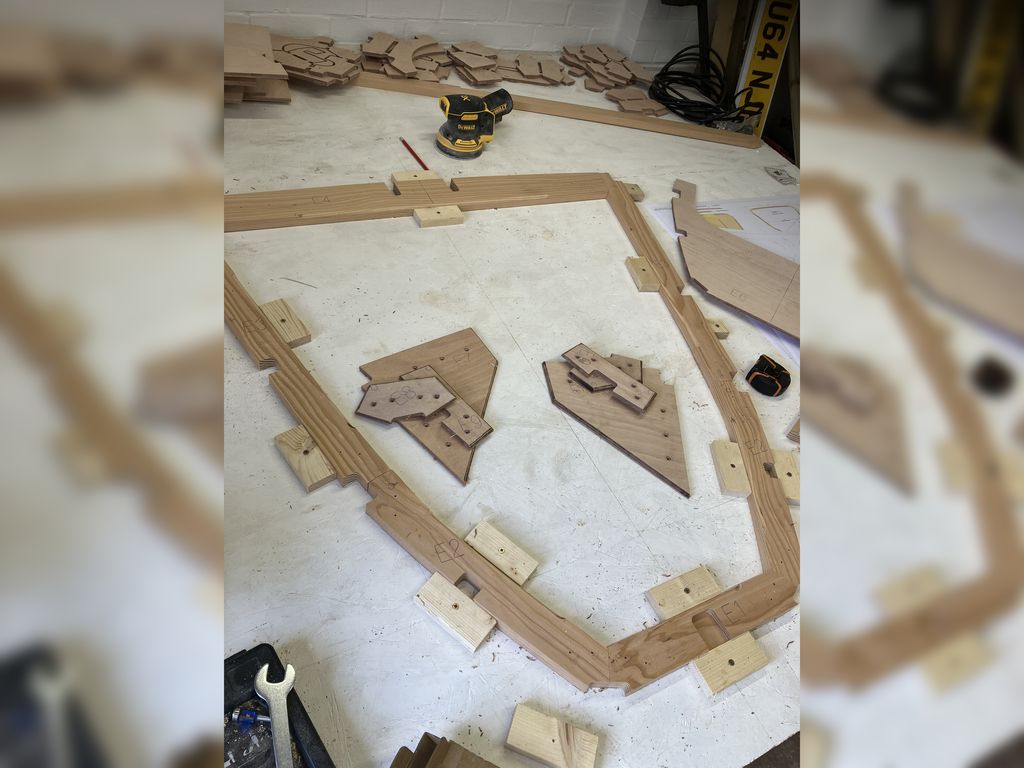

As seems to have become tradition with CG580 builders, I started with Frame E.

Firstly I cut out all the parts on Sheets 1-5, which includes most of the parts for the frames. There are a few on Sheet 10 but I think they're for Frame D' which I'm almost certainly going to do last, so they can wait. Tabs were cleaned up with a flush-cut router bit and frame E laid out. I used a modified Johnson-Oliver method to hold the frames in place - they used kitchen cupboard blocks (which I've since learnt are actually called 'Modesty Blocks', for some reason) which I don't have any to hand but offcuts of pine are just as good.

Relevant sections were rounded off with a 1/4" roundover bit and holes drilled and countersunk. The handheld Dyson did an OK job of clearing the generated sawdust right up until the battery died however I think there may be a proper shop vac in my future soon.

I wetted out the parts to be glued with straight 105/206 (slow) West System Epoxy then added 403 Microfibers to make the adhesive. Knees were glued and screwed then left to cure for about 15 hours. I flipped the frame then glued and screwed the bottom plywood part. The additional deck beam doubler that fits to the aft side of the frame is about 10mm longer on each side than the bow part of the frame. This seemed a bit odd to me but the consenses from the CG580 Builders Facebook group was that it'll get trimmed down later so is fine.

Lessons Learnt

If there aren't any batteries on charge - put some on, you'll need them soon.

Voice assistants are great for setting timers when your hands are covered in epoxy.