Frame S

by on in CG580

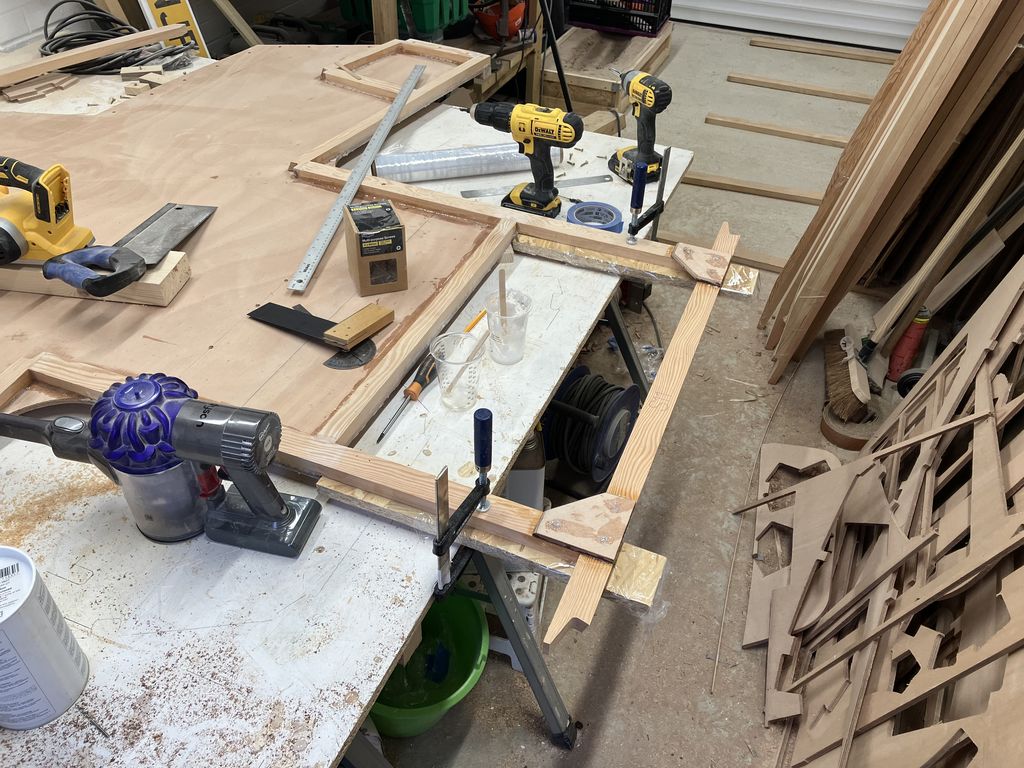

Next up. for no particular reason, was frame S. This frame forms the main entrance into the cabin and is a double-sided frame, i.e. there are douglas fir parts on both sides of the plywood part. This is also the first frame to have parts that need beveling and there is also a plywood butt-block.

I built the 'simple' side of the frame first (the side with no bevels) then build the Beveliser 2500™. This is just a jig that holds the part at the correct angle for the bevel allowing you to plane horizontally across the top giving the correct bevel angle. Using a fixed jig like this does mean that I'll need different jigs for different angles. I did consider making an adjustable jig but frankly it's just not worth the effort. I could have made a double-sided jig with 25° on one side and 16.5° on the other but I didn't think of that until after I had made it.

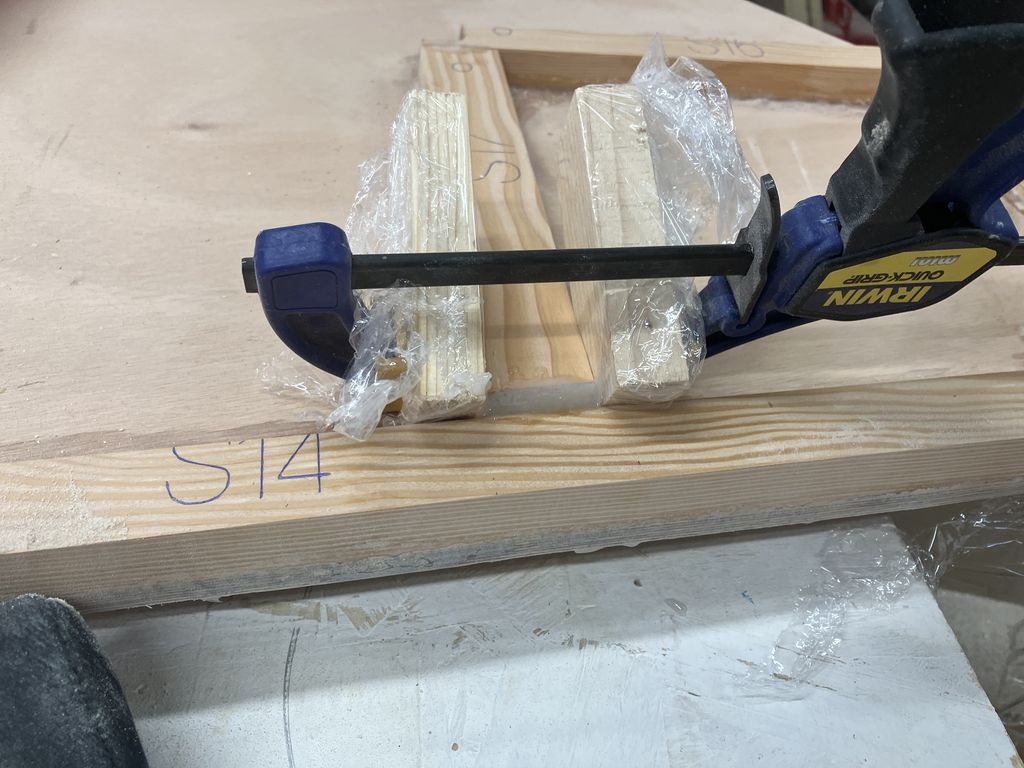

To try to keep the butt-block join as accurate as possible I clamped some lengths of OSB under the joint with some cling film in between to stop the epoxy sticking them on. This kept the joint in-line while the epoxy cured. I also beveled the inside edge of the butt join to give more surface are for the epoxy to stick to. I'm not sure this is really necessary but having a wider joint also means there is less chance of there being a void in it.

The rest of the frame was just a case of gluing it up, screwing, filleting, coating in epoxy and sanding. Time consuming but pretty straightforward...

...until it wasn't...

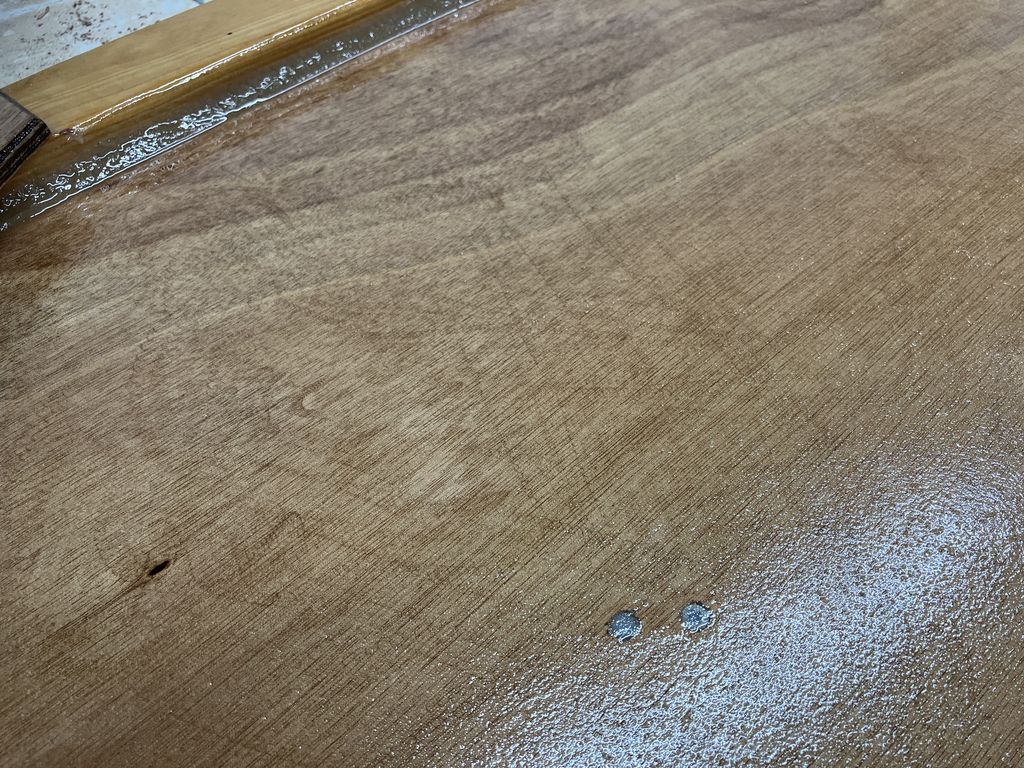

After epoxying the inside plywood some small 'swirls' in the underlying plywood emerged. I pretty certain these either weren't visible before I put the epoxy on, or if they were then they weren't noticible. With the epoxy however, they were very visible. These have come from some sort of debris being caught under the orbital sander whilst I was keying the surface. If I had intended to paint this surface then it wouldn't be a problem but I'd like to go for a two-tone white/natural wood interior and this surface will probably end up being natural wood. Once the epoxy cured I had the joy of sanding it all off again to re-prepare the surface and re-epoxy it. Nor the most fun or rewarding job in the world!

I did have another small issue with the two S5 parts - you can see in the first dry-fit photo that they are both bowed slightly, and bowed in opposite directions (the closer one is raised at the ends and the further one is raised in the middle). The closer one I simply clamped at the ends after gluing but for the further one I used a long piece of wood braced against a rafter to push the centre of the part down. This worked well but the whole frame is slightly warped as a result. Hopefully over time this will settle in time.

The whole build of this frame seemed to take quite a while - partly because it's just a bit more complex with solid wood parts on both sides and partly because I lost a few weekends to both doing actual sailing and watching sailing.