Bunk Sides & Strongback

by on in CG580

The last job before starting to piece all the various bits together was to put the bunk sides together. This really should have been a very straightforward job however I did manage to stuff it up. For butt joints I've been putting a 45° chamfer on the edges under where the butt block sits to slightly increase the volume of epoxy in the joint. When clamping up the joint this 45° angle caused one of the pieces to become dislodged, which I didn't notice until after the epoxy had cured. That meant that I had to plane off the butt block and cut along the joint line, clean up the joint, and re-do it. As it was the 2nd bunk side that I messed up I used the first side as a template for the second one. Even if they're not perfect they should at least both be the same!

I also faced a problem that I knew was coming - the ambient temperature in the garage is now struggling to get above the 16°C that West System 206 slow hardener needs to cure. This probably means that progress will now slow down until temperatures start to rise again in the spring. I have put an electric heater on a smart socket in the garage, which is controlled by my Home Assistant setup, however that's pretty expensive to run so I'm using it as sparingly as possible.

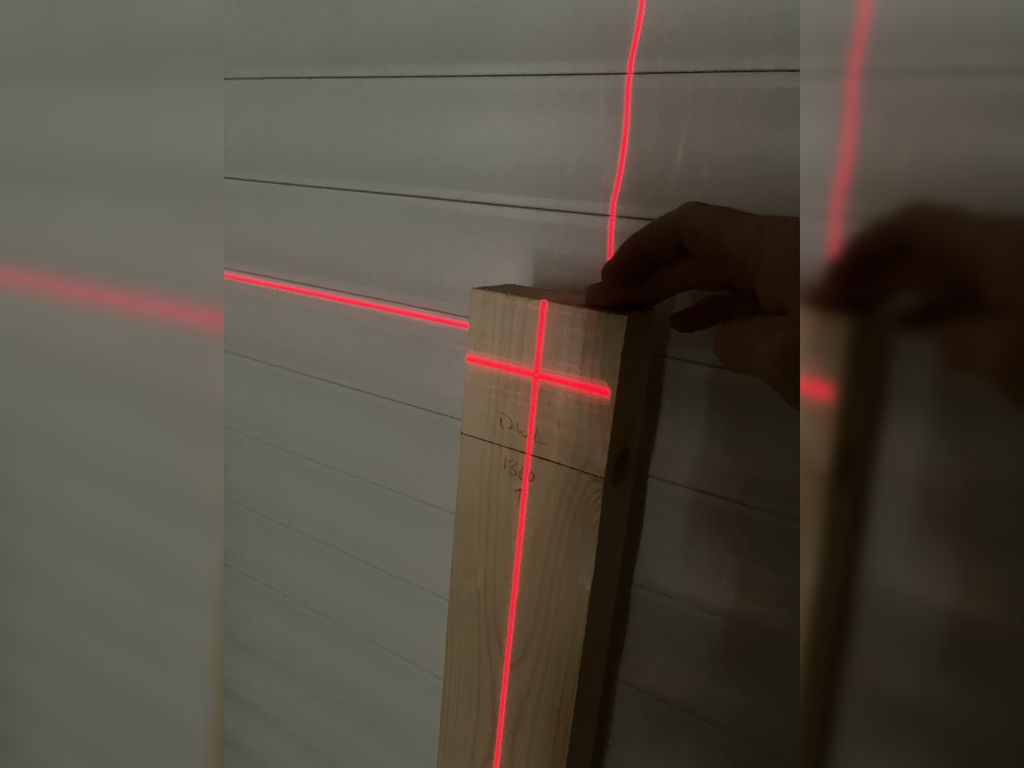

The next job was to build the strongback. I ordered ten 45x145x3600mm beams from Wickes. They were supposed to be kiln-dried but were very wet when they arrived and even after a couple of weeks in the garage one beam was still measuring over 20% moisture content. I did my best to dry them out by using fans to force air up through them which did seem to help.

One busy Saturday saw the bulk of the strongback built and the first few frames mounted. Because the space I'm working in is very tight I need to be careful to not end up with pieces that I can't get into place because there isn't enough space to move them - this meant moving the pieces that will be the hull planking into roughly the right place in the garage before constructing the hull, and also mounting frames T, A and D' before putting the strongback structure in place for the frames near the bow.

Cut List

This was the most efficient cut-list I came up with for 10 x 3600mm beams. Note that I used some left-over CLS timber for the diagonal struts in the strongback so this isn't quite everything.

| Beam | Cut 1 | Cut 2 | Cut 3 |

|---|---|---|---|

| 1 & 2 | 1143mm | 2439mm | |

| 3 & 4 | 1143mm | 2407mm | |

| 5* | 1143mm | 1026mm | 1026mm |

| 6 | 839mm | 1370mm | 1370mm |

| 7 | 702mm | 1400mm | 1400mm |

| 8 & 9 | 1491mm | 1252mm | 819mm |

| 10* | 1491mm | 1491mm |

* Use remainder of these pieces for butt joint.